Fiber Cement Composite

Fiber cement architectural panels are a type of building material commonly used in exterior cladding applications. They are made from a mixture of cement, cellulose fibers (typically sourced from wood pulp), sand, and other additives. These panels are manufactured through a process of pressing or extruding the mixture into flat sheets, which are then cured and cut to size.

Durability: Fiber cement panels are highly durable and resistant to rot, decay, pests, and fire. They can withstand harsh weather conditions, including extreme temperatures, UV exposure, and moisture, making them suitable for various climates.

Low maintenance: Once installed, fiber cement panels require minimal maintenance. They do not need to be painted frequently, and they resist fading, chipping, and warping over time.

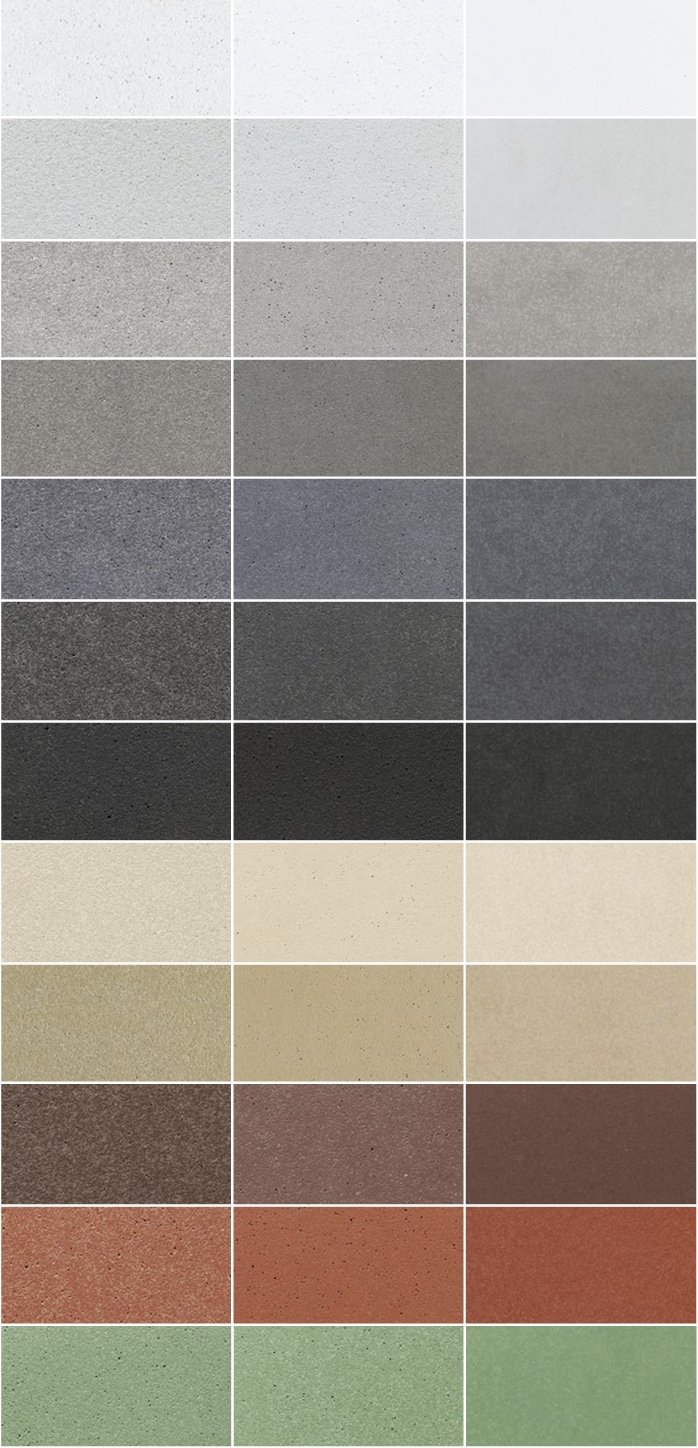

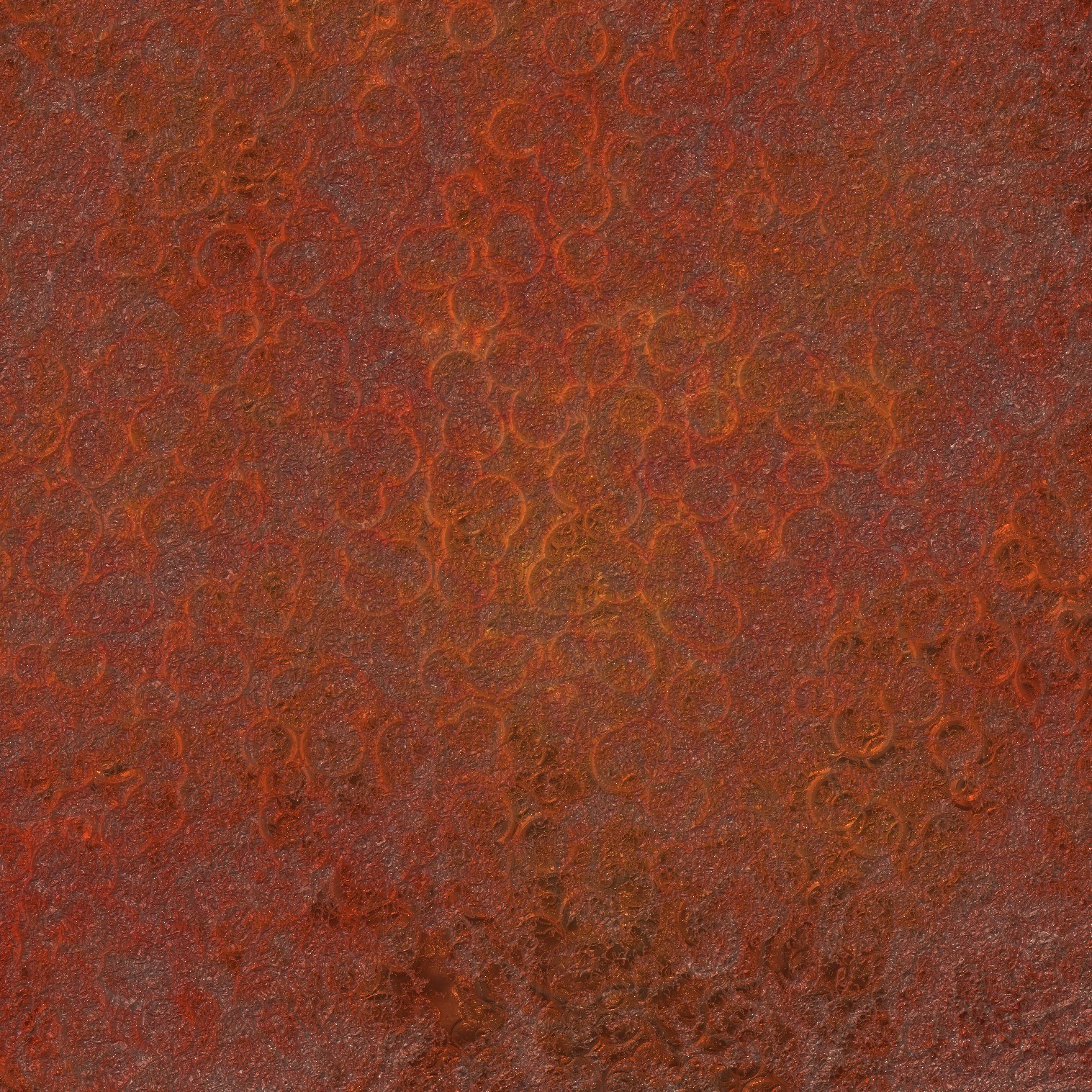

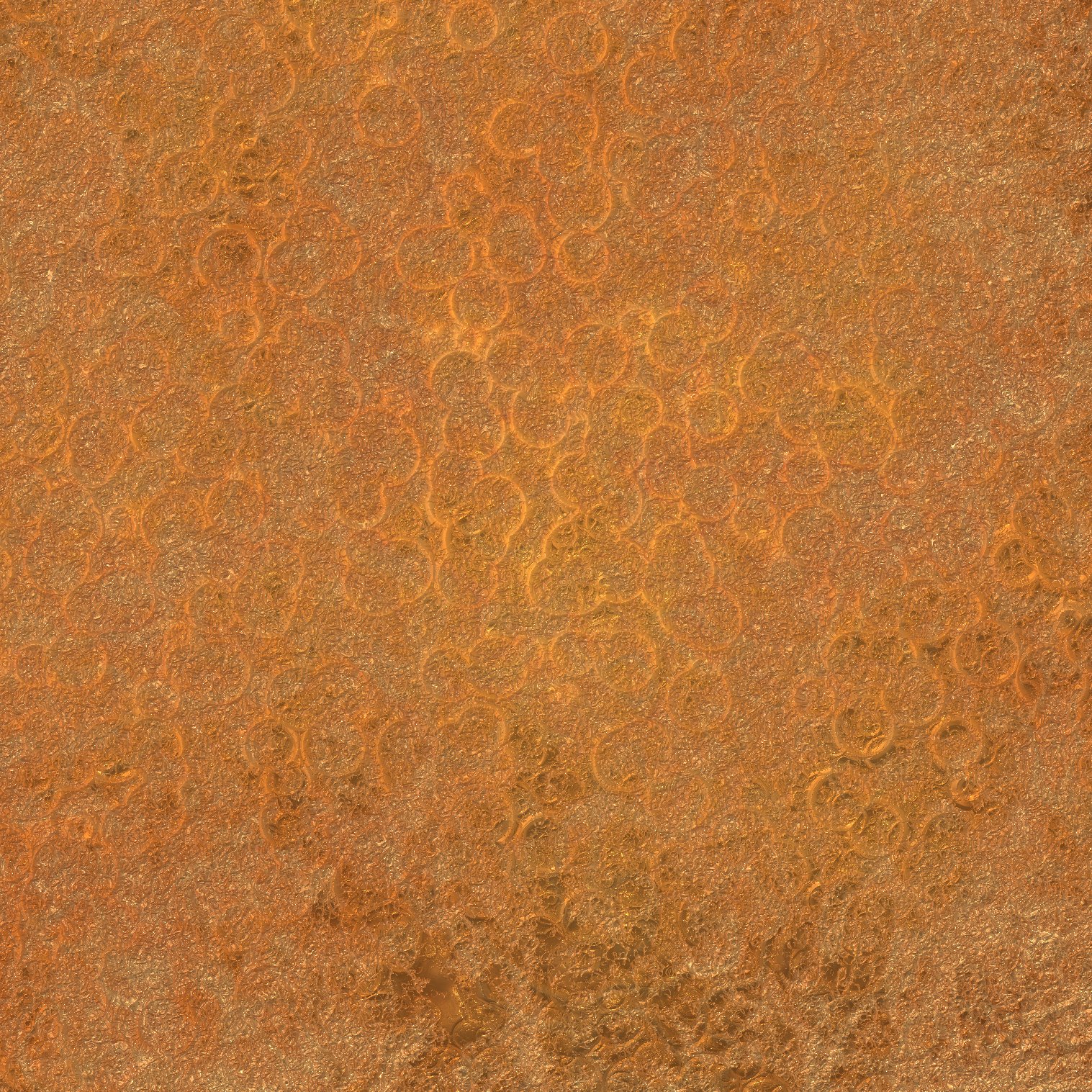

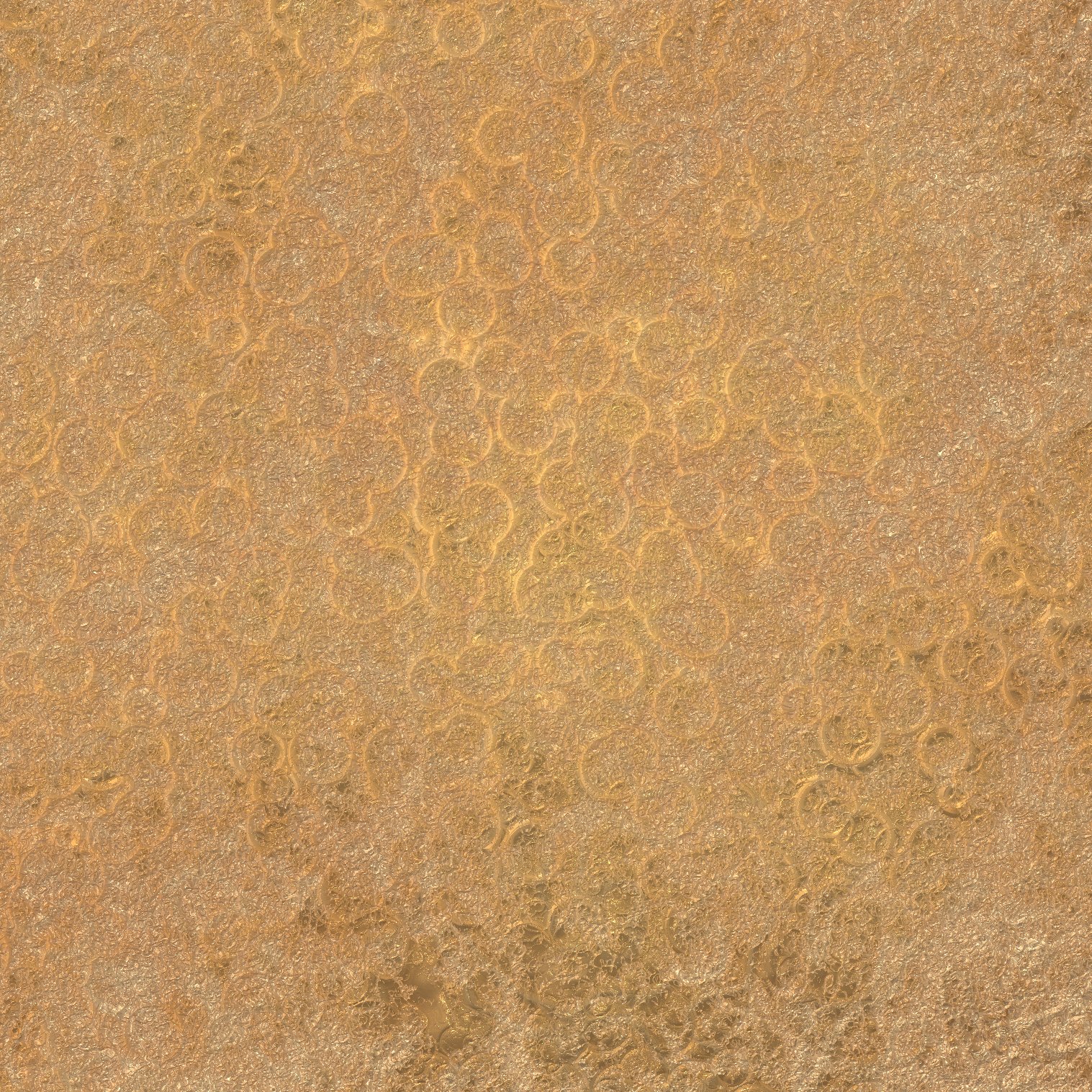

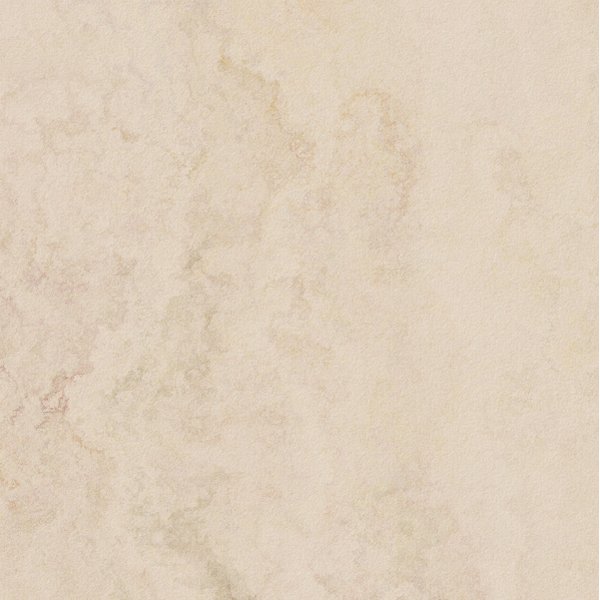

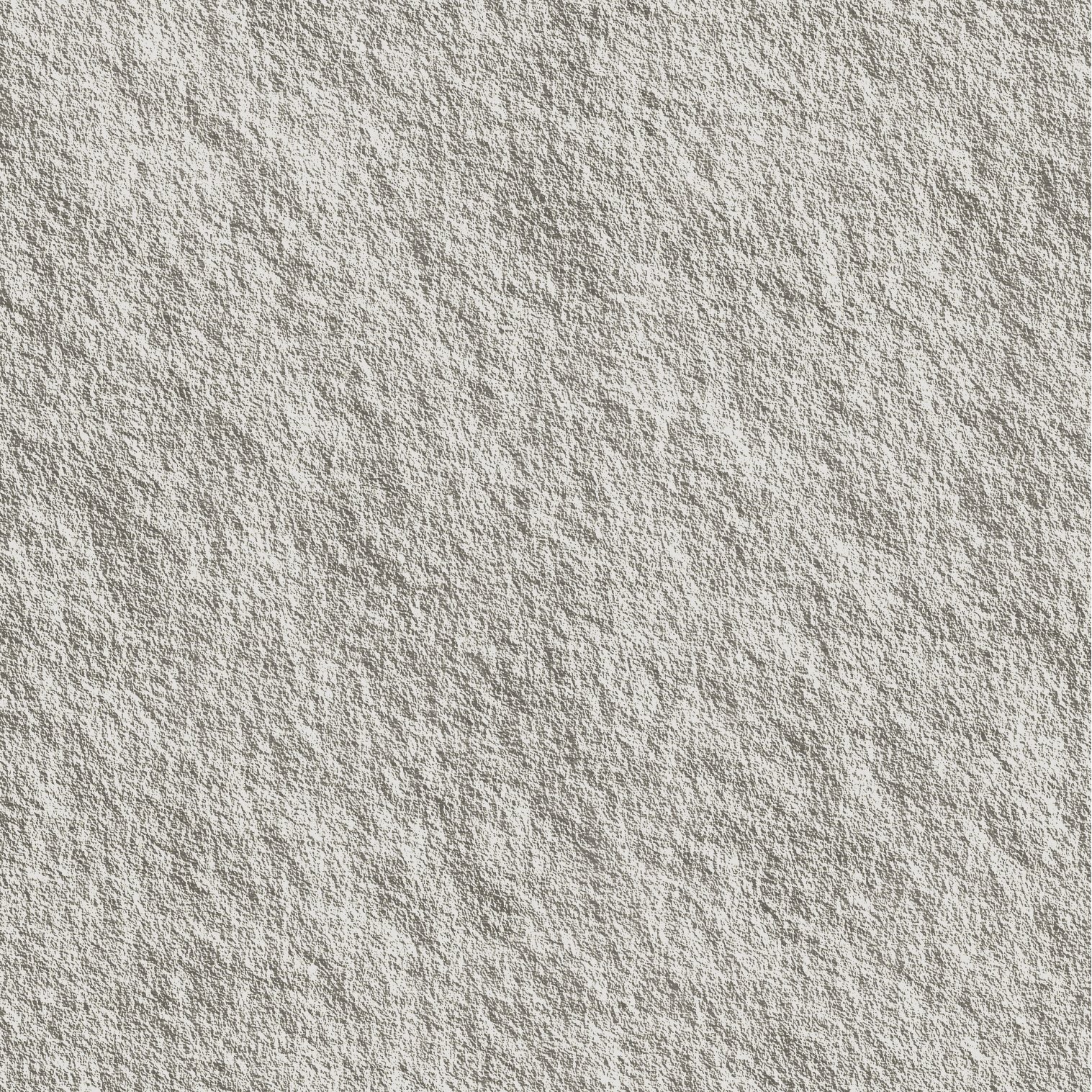

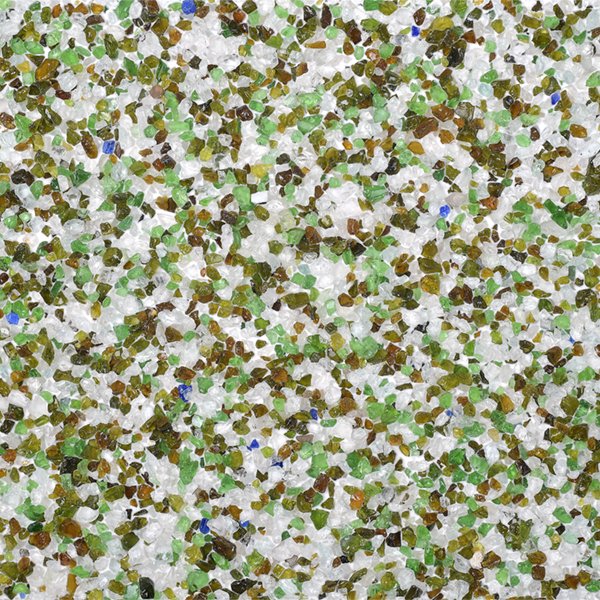

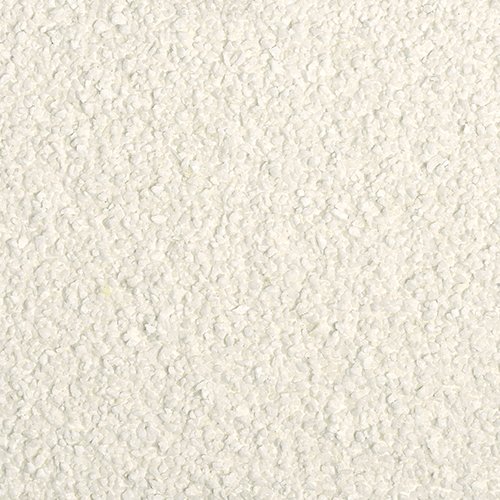

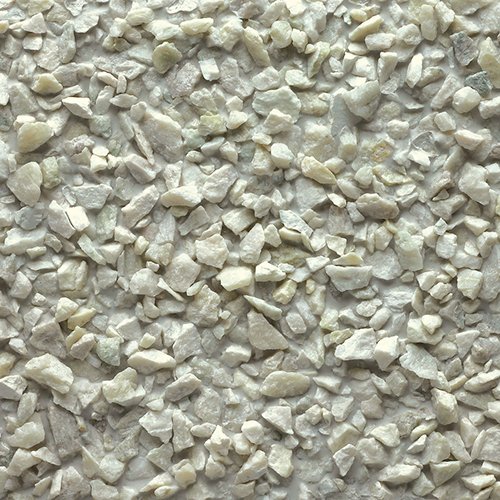

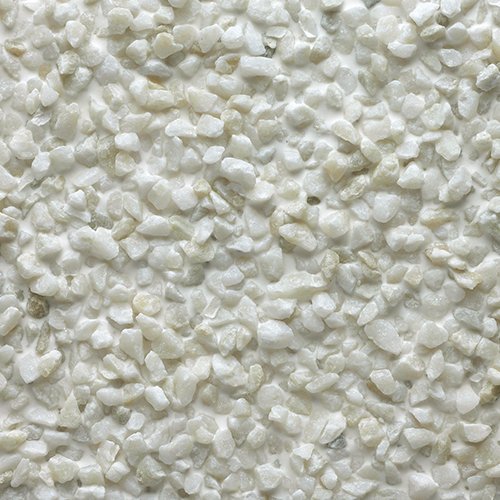

Versatility: Fiber cement panels come in a variety of sizes, shapes, textures, and colors, offering architects and designers flexibility in achieving their desired aesthetic and architectural vision.

Eco-friendly: Fiber cement panels are composed of natural materials, including cement and cellulose fibers, and they can be recycled at the end of their lifespan. Additionally, some manufacturers use sustainable practices and recycled materials in their production processes.

Noise reduction: The density and thickness of fiber cement panels can help reduce noise transmission, improving the acoustic performance of buildings.

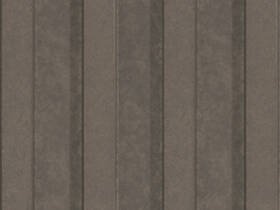

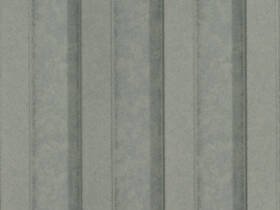

Colours Available